About Us

From Five-Star Generals to Gold-Button Blazers

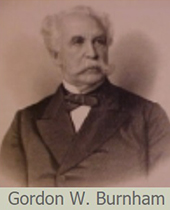

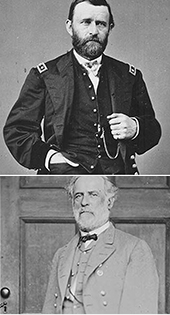

Since 1812, we’ve crafted the world’s most popular metal buttons. When General Ulysses S. Grant met General Robert E. Lee at Appomattox Courthouse, both men wore Waterbury buttons on their chests. Today we make buttons for the fashion industry, professional golf, rowing blazers and every branch of the U.S. Armed Forces as well as across the globe.

With more than 40,000 button patterns in our vault, The Waterbury Button Company can supply you with the perfect button, whether you’re a high-fashion designer, a garment maker in the retail apparel trade or a uniform manufacturer.

Fashion designers prefer Waterbury buttons for their distinctive designs, detail and range of finishes. We can give your career apparel uniform a distinctive look of timeless quality with standard or customized Waterbury buttons.

After the War of 1812, our company was retained to make the metal buttons for all branches of the U.S. Military forces because of our demonstrated ability to reliably deliver the highest quality products. These same abilities brought in contracts from around the world.

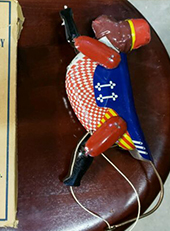

Our company has never lost those incredible attributes of reliability and consistent high quality. As a result, we are the oldest metal button manufacturer in the United States and continue to operate out of Connecticut. We continue to make metal buttons for our global clients like the fashion houses of rag & bone, Ralph Lauren and Brooks Brothers. Additionally, we make the buttons for Disney Cruise Line, the Masters Golf Tournament, and most every railroad, state police department, and fire department across the United States.

You can read through Our History below or Help us write the next chapter.

Contact us or call us at 1-800-928-1812.

Over 200 Years of History

1812

From 1824

1878

1849

1861-1865

1870

1890’s

1912

1917

1920s

1925

1929

1938

1939

1941-1945

1945

1946

1948

1950

1960-1991

1994

1997

1999

2000

2003

2010

2011